-

The Trusted World Champion.

Clean crop intake, robust technology and versatility are the all-important factors. With its wide range of front attachments, the JAGUAR is today at work around the world, harvesting a very wide range of crops.

-

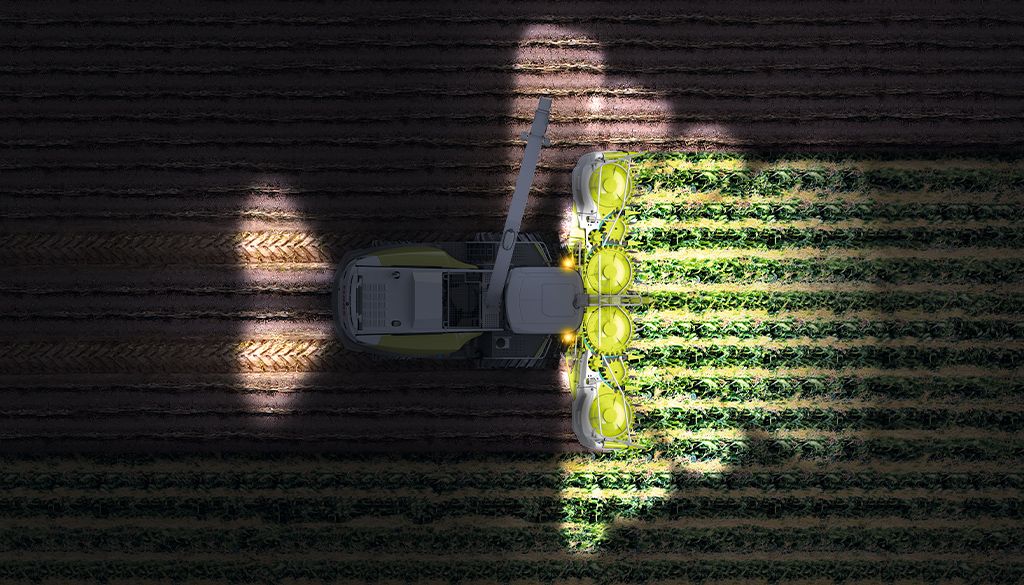

LED Work Lights.

LED work lights on the cab roof and at the rear turn night into day for you. The LED, even-illuminated spotlight on the discharge chute even pivots with the crop flow, allowing night harvesting operations to be easily monitored.

-

Electronic Expertise.

EASY Precision Ag Systems: CAM PILOT, AUTO PILOT, and CANBUS Third-Party Capable

-

ORBIS: Ground Contouring.

Precise ground-contour following is ensured by the redisigned tilting frame in combination with the enhanced CONTOUR / AUTO CONTOUR control system. Excellent lateral compensation is ensured along with ground pressure control.

-

ORBIS: Folding Concept.

The symmetrical folding process allows you to deploy the header from transport width to its full working width in just 15 seconds, At the same time, the integrated ransport chassis is automatically moved into the appropriate position.

-

Ergonomic Cab Comfort.

A new pivoting seat gives the operator increased leg room and a better turning angle. An active refrigerator located under the training seat keeps things cold all day. Dynamic Steering allows the operator to turn the wheels all the way for quicker turns without multiple revolutions of the steering wheel.

-

CEMOS AUTO PERFORMANCE.

With CEMOS AUTO PERFORMANCE, the JAGUAR keeps the set speed constant and regulates engine power and driving speed according to the crop.

-

CEBIS With Touch Operation.

Easy to understand an operate, the CEBIS puts everything at the operator's fingertips with all the main controls integrated into the adjustable armrest. This includes the CMOTION multifunction control lever, a control panel for drive mode, and 12" touchscreen.

-

Superior Crop Flow.

The optimized crop flow of the JAGUAR increases your daily output to a significant degree. The result? Maximum throughput while keeping power requirement to a minimum – leading to impressive fuel savings in terms of fuel per ton.

-

Reliable Crop Transfer.

High strength and a low dead weight are the key characteristics of the chute. The highly concentrated crop stream can be directed more reliably, minimizing wasteful losses. The modular design also enables the system to be adjusted to different working widths.

-

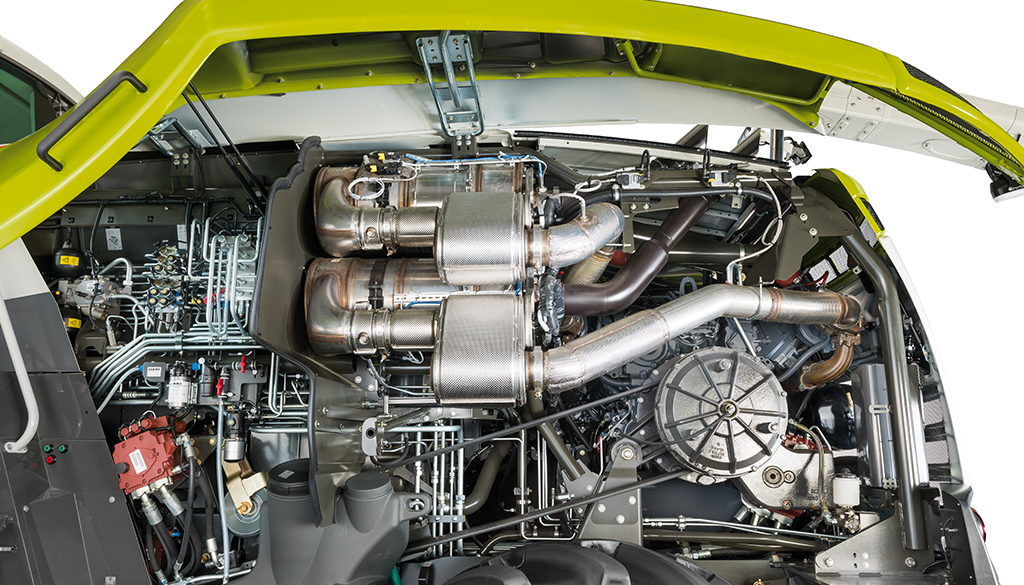

Power and Efficiency.

Equipped with engines from MAN and Mercedes-Benz that comply with all Tier 4 final emission standards via Selective Catalytic Reduction, these engines offer impresive performance from 426 hp ip to 925 hp.

-

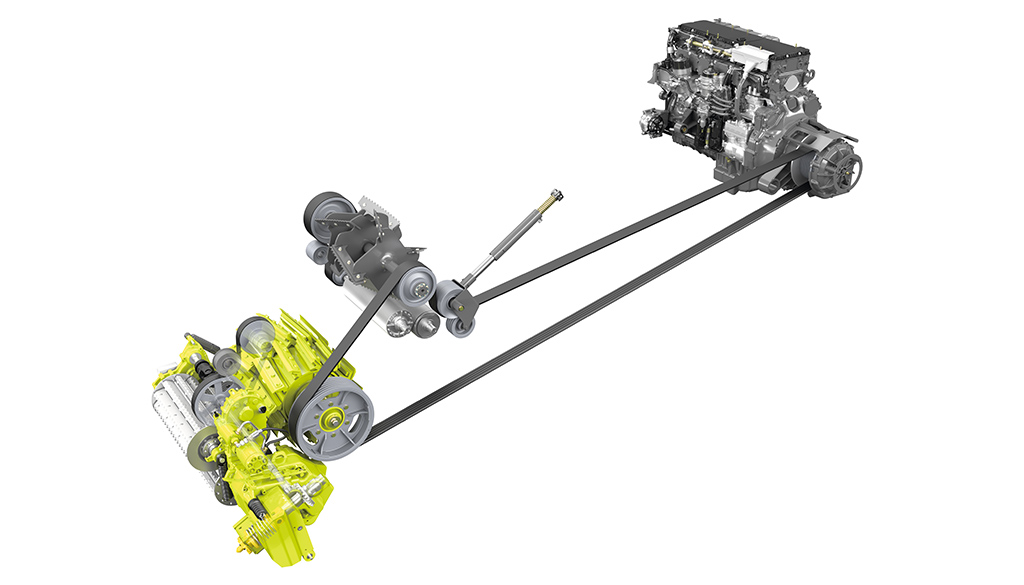

Drive System.

In market comparisons, the drive system of the JAGUAR impresses with its outstanding efficiency. The engine output is matched precisely to the drive systems. The engine is fitted transversely and drives the chopper unit by means of a maintenance-free powerband.

-

Dual Variable Speed Header Drive.

Optional and available in either automatic or manual mode, the intake and the header can be reversed independently and a soft start and stop reduces wear on the clutch.

-

Hydraulic Feed Roll Compression.

Smoother crop flow by automatically adjusting the precompression rollers to maintain constant pressure in all intake heights.

-

Optional TERRA TRAC.

High road speeds of up to 25 mph, smooth header guidance, and excellent stability - the high level of driving comfort of TERRA TRAC has convinced farmers and operators for over 20 years.

-

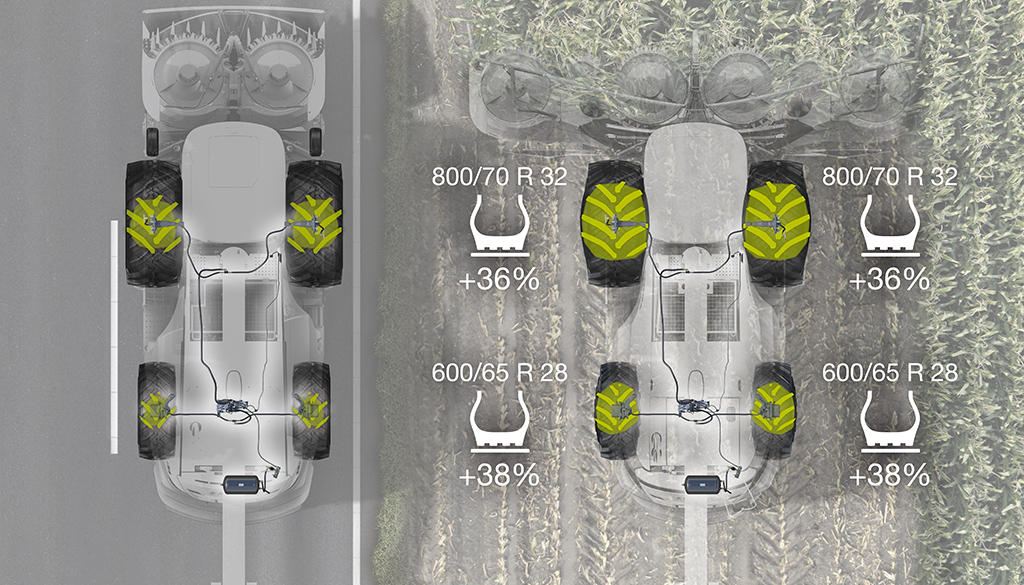

Tire Pressure Adjustment System.

Tire pressure adjustment system for all drive axle and steering axle tires.

-

AUTO FILL.

Using the principal of 3D image analysis, AUTO FILL evaluates camera images to determine the outer edges as well as the filling level of the trailer running along side the Jaguar.

-

LED Maintenance Lights.

Located under the doors and in the mainenance areas. The jaguar also comes with a portable magnetic light and multiple plug-in locations for added convenience when more light is needed.

-

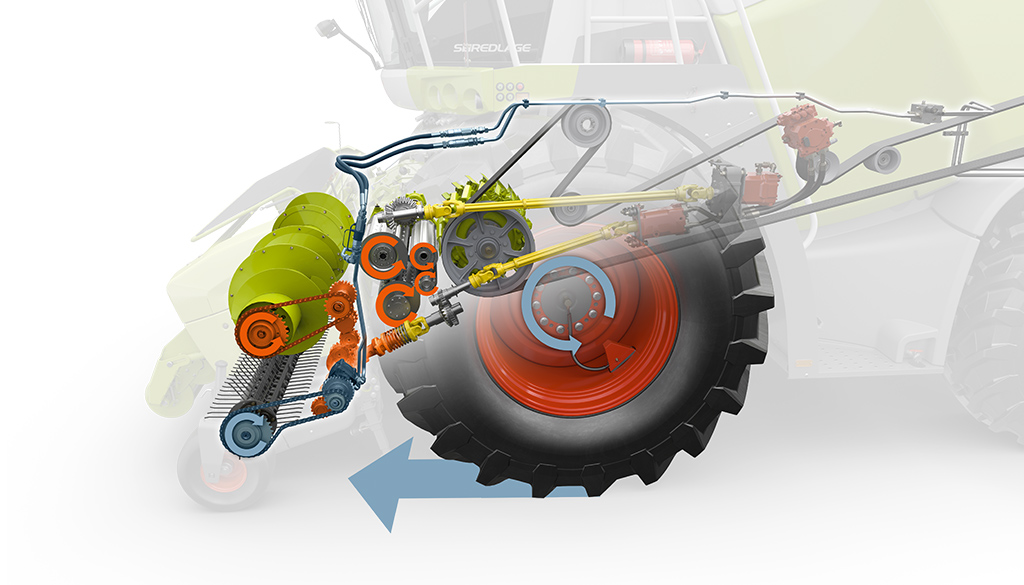

SHREDLAGE.

Rips stalks lengthwise into longer planks and strings - effectively enhancing the fiber content, improving packing and exposing the inner cells of the plant for increased microbial activity while still splitting the corn kernals several times for more complete digestion.

-

DYNAMIC COOLING.

This optional feature identifies the requirements for all three cooling units: engine coolant, charge-air cooling system, and hydraulic oil system. Airflow is directed past the engine and can escape preactically unhindered through the large rear air outlets.

-

ACTISILER 37.

A 9.7 gallon (37 l) insulated tank that can accurately meter inoculant by the ton or by the moisture level from 67.6 - 676 oz/hr (2 - 20 l/h). The system displays volume as well as temperature on CEBIS, operators can automatically switch from ACTISILER to the water tank, and features automatic line cleaning.

-

Determing the Dry Matter.

As well as providing dry matter data, the NIR sensor provides data about the constituents of different crop types. The measuring procedure using near infrared spectroscopy runs continuously during the harvesting process. A light source in the upper discharge chute is directed at the crop as it flows past. The light is reflected back in different ways, depending on the crop moisture level.

-

DYNAMIC POWER.

DYNAMIC POWER PRO automatically reduces engine horsepower to what is needed to maintain ground speed and engine rpm.

-

Ease Of Access: Accelerator Cleaning and Maintenance.

Removinal of the accelerator is made easy for post-harvest cleaning or replacing wear parts.